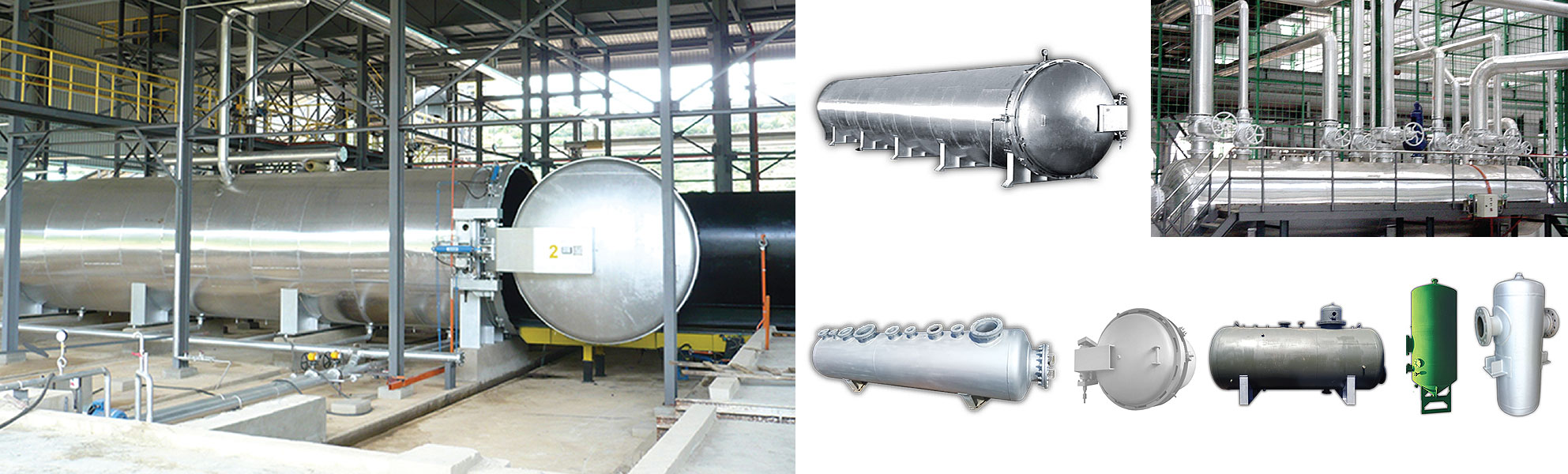

Steam Vessels

We are a licensed Unfired Pressure Vessel Manufacturer and Repairer. Additionally, we are also a licensed Clutch Door Manufacturer. Our steam vessels include Steriliser, Back Pressure Receiver, Steam Separator , Thermal Daerator and Vacuum Daerator. Pressure vessels are Designed, Fabricated & Tested in accordance to globally accepted code such as ASME since the beginning of the process. We believe that Quality Assurance to our clients is one of the most important factor in business success and therefore our Quality Control(QC) performs inspection works professionally. Upon attaining information on actual site situation, we propose the right size of the vessel to meet the actual site requirement.

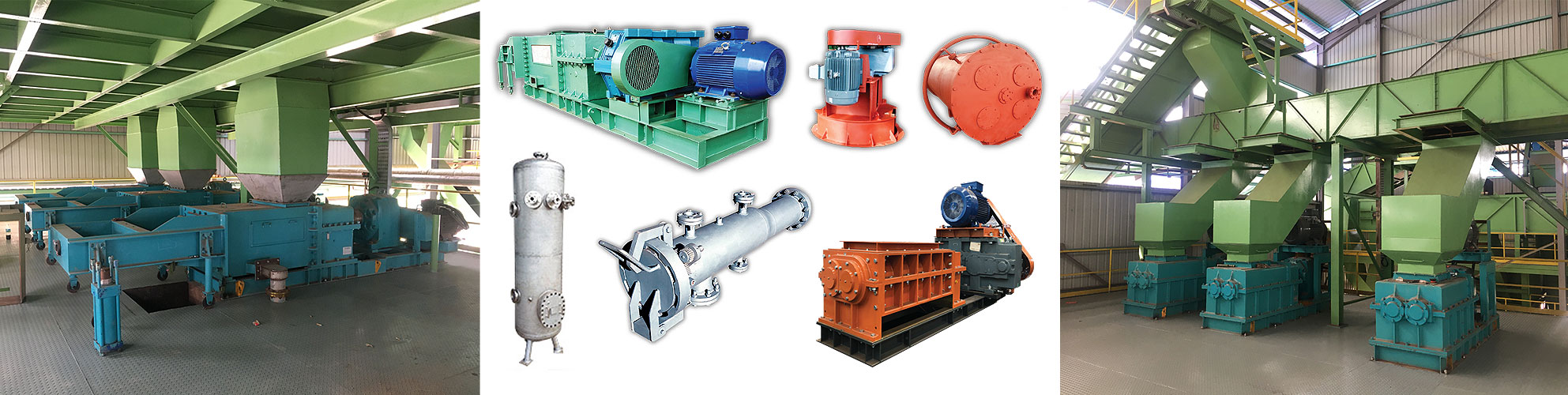

Oil Extraction Equipment

We offer comprehensive range of oil extraction equipment such as Screw Press, Digester, Vacuum Oil Dryer and EFB Treatment machines. Our team design the equipment taking into consideration of ease of maintenance, durability, good performance, cost and spare parts availability. The complementary parts such as gearbox, motor, transmission etc are sourced from reliable &competent vendors. Equipment are tested with raw material to ascertain its performance. Various sizes of the equipment are available and select the optimum size to meet client’s requirement.

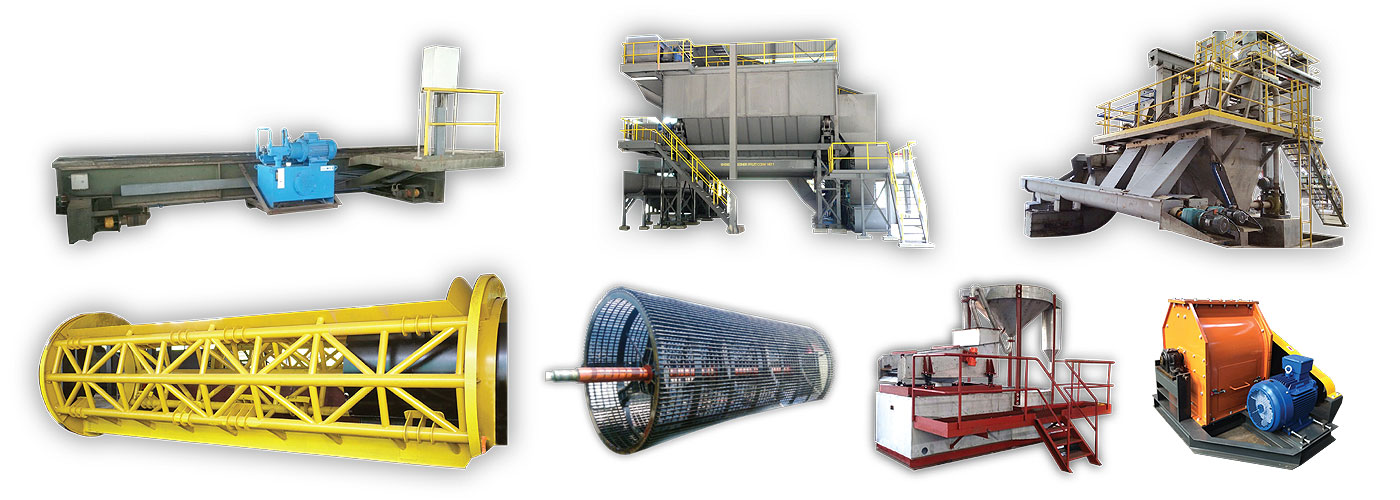

Water Treatment Equipment

Other Unfired Pressure Vessel we produce and offer are pressure sand filters and Softener. Internal surface are blasted according to SA2-1/2 and painted with Epoxy Food Grade Paint. End user have to options to request us to supply integral piping together with valves, resin (water Softener) and Filtering material (Sand Filter). We design our bottom distribution system with PP nozzles which ensures uniform distribution of flow of water.

Electrostatic Precipitator (ESP)

We supply Double-Filter ESP system from reputable & reliable vendor and we are a competent ESP installer. Other essential items for operation of ESP are designed, fabricated & Installed to ensure a successful commissioning. One of the challenges of Integrating ESP into existing plant is the Ducting Design to suit the Boilers outlet and others. Project Schedule is very important and therefore we carried out 3-D modeling of the entire fabricated parts and a detailed plan before installation.

Spare Parts

MJ Group is a one-stop centre for all spare parts normally required in palm oil mills. We supply spares ranging from locally manufactured castings to OEM components of established imported proprietary equipment.

We work closely with the palm oil millers to ascertain and satisfy their parts needs for supply in time for preventive maintenance, thereby eliminating their holding costs as well as avoiding costly downtime stoppages.

Please refer to Excelmech Engineering for more details about our products and spare parts.